Forged aluminum discs and custom blanks are essential for high-strength and precision-engineered parts across aerospace, automotive, machinery, and energy industries. Chalco supplies forged discs in 6061, 7075, 2024 and 5083 alloys, covering diameters from Ø100 to Ø2700 mm with machining tolerance up to ±0.05 mm. Each forging undergoes heat treatment and NDT inspection to ensure structural integrity, wear resistance, and long service life.

From forged gear discs with center holes to close-tolerance circle plate blanks, we provide tailored forging and CNC machining solutions to meet diverse design and performance needs. With fast quotations, global delivery, and full documentation support, Chalco helps you move seamlessly from concept to production.

- Product Overview of Forged Aluminum Discs & Blanks

- Types of Forged Discs — Gear Discs, Center Holes & Custom Blanks

- Forged Disc Material Grades — 6061, 7075, 2024, 5083

- Applications of Forged Discs in Automotive, Aerospace & Industry

- Chalco Forging Advantages — Precision, Tolerance & QA

- Forged vs Rolled/Cut Discs — Selection Guide

- Forged Disc FAQ & Quote Requests

Product Overview of Forged Aluminum Discs & Blanks

Chalco offers high-performance forged aluminum discs and blanks designed for structural, load-bearing, and precision-machined applications. Manufactured by open-die or closed-die forging, they deliver refined grain flow, excellent strength-to-weight ratio, and superior fatigue resistance — making them ideal for aerospace, energy, transportation, mold tooling, and industrial equipment.

Available Forms: solid blanks, center-hole/bored discs, flanged hubs, and fully customized geometries.

Size Range: Ø100 mm to Ø2690 mm in diameter, thickness 20 mm to 600 mm. Precision CNC machining (rough/finish turning, milling) and heat treatment (O, T6, T651, T7451) available on request.

Alloy Options: 6061, 7075, 2024, 5083, 6082, 2618, 7050. Other materials such as titanium or stainless steel can also be supplied upon request.

Supply & Delivery: Chalco maintains stock for standard sizes and alloys, ensuring fast delivery and support for low-volume customization. Send your drawings/specifications and our engineers will provide a tailored proposal with machining allowance recommendations — reply within 24 h guaranteed.

-

Large-Diameter Forged Disc

Aluminum forged discs up to 106 inches (2690 mm) diameter, suitable for large aerospace and energy components requiring superior structural integrity, dimensional stability, and precision machining.

-

General Forged Blank

Basic aluminum forging blanks for molds, structural parts, and subsequent heat treatment. Available in round, square, or customized shapes with close-tolerance allowances.

-

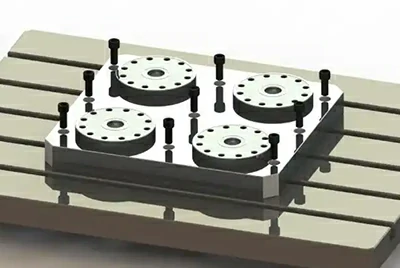

Solid Forged Disc

Solid aluminum forged discs with uniform cross-sections and high density, ideal for high-load rotating parts such as flywheels, bases, and pressure plates; supports finish-machined surfaces per drawing.

-

Forged Disc with Center Hole

Aluminum discs with center holes (pre-bored/reamed), threaded holes, or positioning holes to reduce downstream machining for bearing seats, flanges, and couplings.

-

Forged Disc with Raised Hub

Discs with integrated bosses or reinforced edges to improve torsional rigidity and load transfer — typical for wind-turbine shaft ends, aerospace rotary joints, and mechanical couplings.

-

Forged Disc with Recess/Groove

Pre-formed ring grooves, keyways, and process holes to enhance assembly accuracy for heavy-duty or complex applications; suitable as gear-seat discs and precision circle plates.

-

Forged Hub

Aluminum forged hubs with integrated center sections for enhanced structural strength; widely used in aerospace connectors, shaft flanges, mechanical couplings, and wind-turbine components.

-

Custom Forged Disc

Custom aluminum forged discs with complex contours, asymmetrical structures, multi-step geometries, or specified close-tolerance machining allowances — for molds, precision machinery, and high-end equipment covers.

If you're unsure about the exact forged disc type or specifications, contact Chalco engineers. We will recommend the most suitable aluminum alloy, structural type, and processing method based on your application, machining requirements, and assembly conditions. Send your drawing to receive specifications and a quote within 24 hours.

Forged Aluminum Disc Materials & Alloy Grades

Aluminum alloy forged discs combine lightweight, high strength, fatigue resistance, and machinability, making them ideal for aerospace, transportation, automation, and mold tooling. Chalco applies advanced heat treatment and precision machining to deliver close-tolerance forged blanks with full certification and mechanical test reports.

-

6061-T6/T651 Forging

Balanced strength, weldability, and heat treatment response; suitable for general structural forged discs and medium-load parts.

-

7075-T6/T73 Forging

Ultra-high strength with excellent fatigue resistance; widely used for gear discs, flywheels, support plates, and aerospace nodes.

-

2024-T42/T6 Forging

Excellent fatigue resistance and toughness, suitable for rotating forged discs exposed to repeated stress.

-

7050-T7451 Forging

High strength with stress corrosion resistance; ideal for thick-walled and heavy-duty forged blanks.

-

2219-T6 Forging

Outstanding high-temperature resistance; used in aviation fuel systems, hot-end trays, and thermal-resistant discs.

-

5083-O/H112 Forging

Good corrosion resistance and plasticity; suitable for marine covers, chemical industry forged discs, and equipment end caps.

We also offer forged discs in specialized alloys such as 7475, 6082, 2618 and more, customized to drawing specifications and heat-treatment requirements. Other materials like titanium and steel are available on request.

Send your drawing for alloy selection and a quotation within 24 hours.

Chalco Forging Capabilities — Precision Aluminum Discs & Close-Tolerance Blanks

When sourcing forged aluminum discs, customers often face challenges such as alloy selection, tight dimensional tolerances, fast turnaround, and reliable quality. As a specialized aluminum forging supplier, Chalco provides integrated solutions from raw billet to precision-machined forged blanks, ensuring every disc meets international engineering standards.

Comprehensive Manufacturing Capabilities for Aluminum Forgings

Chalco offers advanced open-die and closed-die forging processes optimized for aluminum alloys. We produce forged discs from Ø100 mm to Ø2500 mm and up to 8 tons. Product types include solid discs, center-hole discs, raised hubs, flanged discs, and custom forging blanks according to drawings. Our key capabilities include:

- High-tonnage forging presses ensuring refined grain flow and stable mechanical properties

- Precision CNC turning, milling, drilling — close tolerance up to ±0.05 mm

- Heat treatment processes: annealing, T6/T651 aging, quenching, tempering, stress relieving

- Industry coverage: aerospace, automotive, rail, energy, molds, and industrial equipment

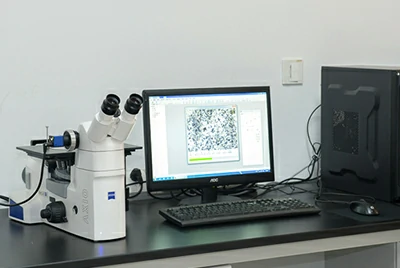

Reliable Quality Assurance & Technical Support

Every Chalco forged disc is supplied with EN 10204 3.1 certificates, heat-treatment records, and inspection reports. Third-party certifications (SGS, TÜV, BV) are available on request. Our quality assurance includes:

- Ultrasonic Testing (UT) for internal defect detection

- Coordinate Measuring Machine (CMM) inspection and precision gauges

- Metallographic analysis, tensile and hardness testing

- Rapid delivery program — standard forged discs shipped within 7 days

- Engineering support from alloy selection to drawing optimization and process recommendations

Chalco also supports custom forged discs with special geometries, non-standard dimensions, and integrated hubs or flanges. Send us your drawings today for a tailored process and fast quotation (24h response).

Beyond discs, Chalco manufactures a wide range of forged aluminum components for structural, sealing, and motion applications:

Forged Aluminum Bar

Round, flat, and square bar options for high-load applications.

Forged Aluminum Block

For mold bases, heavy-duty machining, and tooling systems.

Forged Aluminum Plate

High-strength forged plates for aerospace and structural uses.

Forged & Rolled Ring

For rotating assemblies, flanges, and mechanical couplings.

Forged Shaft

Precision shafts for power transmission and industrial systems.

Forged Tube & Fitting

High-pressure aluminum pipe components for sealing and flow control.

Forged vs Rolled/Cut Aluminum Discs — Selection Guide

Chalco provides aluminum discs via multiple manufacturing routes, each suited to different structural and performance targets. Use the guide below to choose the most suitable option for your application, tolerance, and cost requirements.

- High Load & Fatigue Resistance → Forged Aluminum Discs: Forging creates continuous grain flow and a dense structure for superior strength, impact, and fatigue performance. Best for gear discs, center-hole discs, hubs, and critical rotating parts in aerospace, energy, and heavy machinery. Typical finish-machined tolerance to close-tolerance specs per drawing.

- Cost-Effective & Dimensional Stability → Rolled (Plate-Cut) Discs: Discs are cut from hot-rolled or forged plates; good stability and availability for large-scale production with moderate strength needs. Ideal for covers, bases, fixtures, and non-critical rotating elements where material utilization and cost efficiency matter.

- High Precision & Clean Edges → Precision-Cut Aluminum Discs: CNC/laser/waterjet cutting from plate or rod for tight flatness, minimal thermal distortion, and clean edges — suitable for sealing surfaces and precision assemblies. Typical dimensional accuracy can reach ±0.05 mm depending on thickness and diameter.

Chalco supplies forged, rolled, and precision-cut aluminum discs and will recommend the optimal route based on your load case, tolerance, surface finish, and budget. Send your drawing for engineer review and a 24-hour quotation.

Aluminum Forged Disc Application Fields & Solutions

With exceptional strength, precise dimensional stability, and superior fatigue performance, aluminum forged discs are widely used in high-end industries. Chalco delivers customized aluminum forged discs from blanks to precision semi-finished components, ensuring structural integrity and high assembly efficiency in demanding environments.

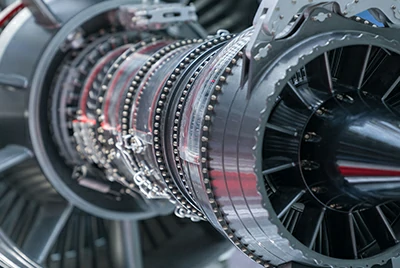

Aerospace-Grade Forged Discs & Rotating Components

Chalco's aerospace-grade aluminum forged discs are widely used in turbine discs, engine flanges, structural connectors, and fatigue-resistant rotating parts. These forged components meet stringent weight-to-strength and reliability requirements, supporting close-tolerance finishing for high-precision assemblies.

| Application Area | Recommended Alloy | Features |

| Turbine disc / flywheel | 7075-T6 | Ultra-high strength, excellent fatigue resistance |

| Engine end cover | 2219-T6 | High-temperature resistance, hot-end structural stability |

| Structural flange connector | 7050-T7451 / 2024-T42 | Stress corrosion resistance, durable under dynamic load |

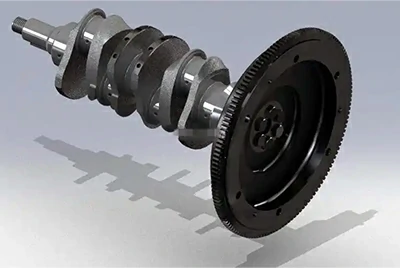

Automotive & Motion Systems — Precision Forged Discs

Chalco supplies precision-forged aluminum discs for automotive and automation systems, such as robotic bases, rotating platforms, gear-seat flanges, and center-hole discs — where tight tolerances and machining stability are critical to performance.

| Application Area | Recommended Alloy | Features |

| Chassis connection plate | 6061-T651 | Good weldability and stable structure |

| Gear support flange | 2024-T6 / 7075-T73 | High rigidity and vibration resistance |

| Brake disc substrate | 6082-T6 | Thermal conductivity and fatigue strength |

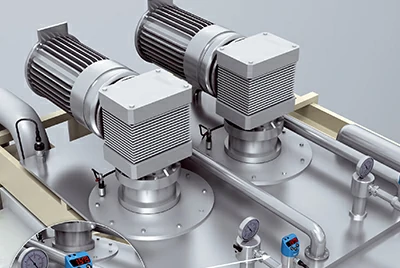

Energy & Power Equipment Forged Discs

Aluminum forged discs are widely used in wind turbines, generator flanges, and couplings that require corrosion resistance and dimensional stability over long operating periods. Typical configurations include raised-hub flanges and center-hole discs for accurate alignment.

| Application Area | Recommended Alloy | Features |

| Wind turbine main shaft end plate | 7050-T7451 | High strength and dimensional consistency |

| Generator flange connector | 5083-H112 | Marine-grade corrosion resistance, weldability |

| Coupling adapter | 6082-T6 | Impact toughness, excellent machinability |

Defense & Rail — Heavy-Duty Forged Discs

Chalco delivers military-grade and transportation aluminum forged discs for flywheels, turret bases, and protective end caps — where impact resistance, structural strength, and fatigue reliability are essential.

| Application Area | Recommended Alloy | Features |

| Turret rotating base | 7050-T7451 | Impact-resistant and lightweight |

| Flywheel / rotating body | 7075-T6 | Fatigue resistant, dimensionally stable |

| Protective end caps | 2024-T6 | High strength and toughness for dynamic loads |

General Machinery & Mold Manufacturing

Aluminum forged discs are widely used in mold bases, hydraulic units, and precision turntables that require high processing precision, good toughness, and repeatable accuracy in assembly. Close-tolerance finishing and flatness control help reduce downstream machining time.

| Application Area | Recommended Alloy | Features |

| Mold platen / insert block | 6061-T6 | Good machinability and thermal stability |

| Hydraulic end cap / base | 7075-T73 | High strength and pressure resistance |

| Assembly turntable / interface plate | 5083-O | Corrosion resistance and tight-tolerance fit |

Chalco supports customers from early-stage structural design to volume production. We provide alloy recommendations, heat treatment state selection, and CNC machining strategies to help ensure smooth project ramp-up and long-term part stability. Send your drawing for an engineer review and a 24-hour quotation.

Frequently Asked Questions About Aluminum Forged Discs

What's the difference between aluminum forged discs and forged blanks?

Aluminum forged discs have more defined geometry and optional surface preparations (e.g., center holes, flanges), while forged blanks are near-net aluminum forgings intended for subsequent CNC machining or shaping per drawing.

What are the advantages of forged discs compared to cut aluminum discs?

Forged discs exhibit continuous grain flow, high structural integrity, and significantly better fatigue performance than discs cut from plate, making them ideal for high-load and rotating applications.

Can Chalco produce aluminum forged discs with customized structures?

Yes. We support custom forged discs with center flanges, hubs, chamfers, keyways, center holes, and other features per your drawings, including rough/finish machining allowances and close-tolerance requirements.

Which forging methods are available, and how should I select?

We offer open-die (free forging), closed-die (precision forging), and partial upsetting. Open-die suits large, low- to mid-volume, or non-standard shapes; closed-die is ideal for smaller, higher-volume, or repeatable geometry with tighter tolerance control.

Can I purchase aluminum forging blanks without additional processing?

Certainly. Delivery options include forged blanks only, heat-treated blanks, or semi-finished precision-machined discs to fit your internal processing schedules.

What heat-treatment conditions are available for aluminum forged discs?

Typical conditions: O (annealed), T6, T651, T73, T7451. We recommend the condition based on your application, and provide full heat-treatment documentation with each shipment.

Can aluminum forged discs be used directly for sealing or precision assembly?

Yes. Depending on size and thickness, dimensional accuracy can reach ±0.05 mm with controlled flatness, surface finish, and hole positioning. Specify targets (e.g., flatness Ra/parallelism/hole true position) and we'll tailor the process accordingly.

Do you provide testing and certification for forged discs?

Yes. We supply EN 10204 3.1 certificates, UT reports, and mechanical test results; third-party verification (e.g., SGS/TÜV/BV) is available on request.

Have more questions or custom requirements? Send your drawings/specs — our engineers will respond within 24 hours with alloy selection, tolerance proposals, and pricing.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote